The three most important things about selling on line are 1- the photograph 2- the photograph and 3- the copy. Let’s face it when someone is scrolling through thousands of available products you have about a 60th of a second to catch their eye and then you have a moment to get their attention.

peeking through the curtain

backstage

When I first opened my online shop one of the first things I did was search for something that I also make. For example, a teapot. Then after scrolling through the first five pages I jumped to page 12,879. I found photos that were dark, out of focus, and swamped by the fussy background. In order to eliminate the problem of too dark and fuzzy is to use a tripod. You can shoot at very slow shutter speeds to allow enough light in without moving during the shot. Auto focus has been a real help since my eyes aren’t getting any sharper but if you have the option to shoot in different modes you may need to set the focus area. It’s important to try to focus in a mid point of a 3-D item so the whole item is in focus not just the front on the rim. Using a small aperture (the bigger the f-stop number the smaller the opening) also creates a bigger “depth of field”. This means that more of the item, front to back will be in focus as opposed to just a thin front to back slice being in focus. Of course the smaller the opening, the longer the exposure time to get enough light making a tripod essential.

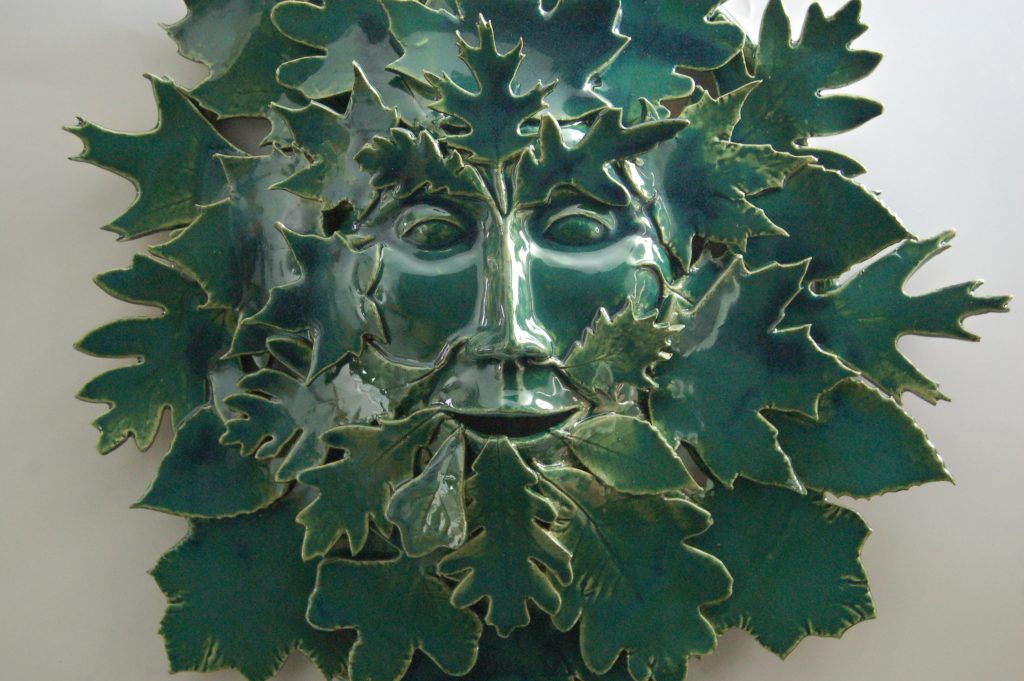

Disclaimer here, I don’t know anything about cell phone photography, smart or otherwise. I use a digital SLR camera and I learned with film cameras. I’m sure someone out there has come up with a tiny tripod for phone cameras. No matter what camera you use, photos are still all about light so let’s start there. I like to use natural light and I often shoot pictures of my Greenmen outside on the east side of the house in the afternoon shade. I tack a piece of backdrop onto the wall with a hole at the screws for hanging the piece.

shooting outside, creating my own shade

One of the drawbacks of using natural light is conditions are not always optimal. An overcast day on the shady side of the building is best. However you can create some overcast by tacking a large piece of semi sheer fabric at the top of the backdrop for the piece and drape it over you and camera to diffuse the sharp reflections that occur on a bright sunny day. I have also used a canopy with poster board covering the gap to create more shade for my green man photos. If you look closely you can see the reflections of the trees in the background.

everything reflects in a dark shiny surface

the backdrop is attached to the ceiling on a roller

my table with backdrop, curtain and tripod

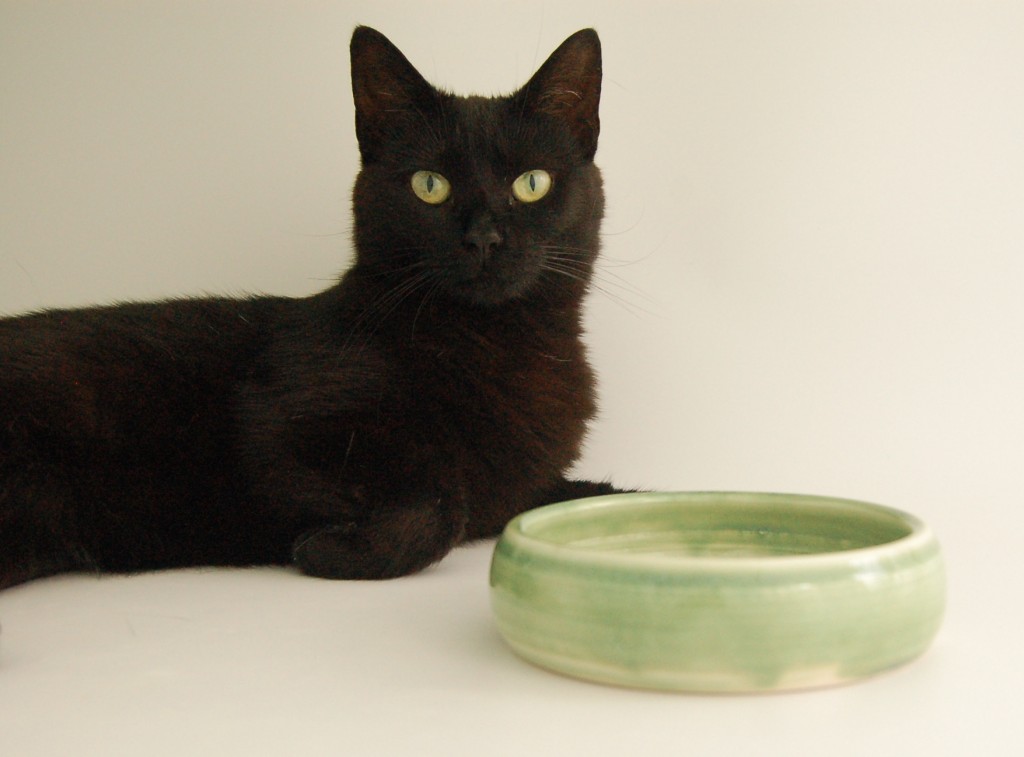

Most of my items are smaller than the Greenmen and I shoot these on my table with a translucent white backdrop that is hanging from the ceiling and can be rolled up when not in use. I also hang some sheer white fabric in front of the table to give a uniform look to the highlights, eliminate reflections and bounce more light on the subject.

The light comes from a west window so I shoot before the sun gets too low. I can also open a door if the light is dim , for example on a rainy day. I also use a piece of white poster board on the dark side to bounce more light back onto the shadows. A few highlights and a gentle shadow are fine and help show the dimensions of the piece. If you don’t have a window handy a lamp will do. You may have to try different white balance options to find the one that gives the truest color balance.

If the item has a shiny dark surface using a piece of black fabric or paper in front of the item will eliminate reflections of every item in the room. Cut a hole or a long vertical slit for the camera lens to peek through.

Greenman on a white background with a black cloth hanging in front to eliminate reflections

I’m able to make any adjustments needed using the photo app that came with my computer, color balance and exposure are the most used along with cropping, fill up that screen. Think of your photograph as another work of art and really look at it. Keep notes and keep trying, you’ll get better.